Welcome to Dongguan Yinso Medical Packaging Co.,Ltd.

Welcome to Dongguan Yinso Medical Packaging Co.,Ltd.

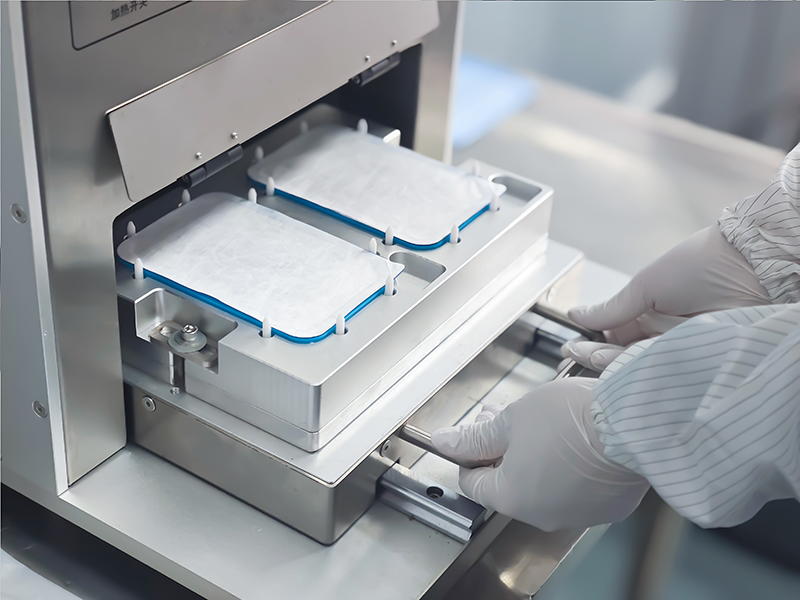

In the medical field, sterility is the lifeline of safety. Serving as the "protective garment" for medical devices, packaging systems composed of medical breathable paper (like DuPont™ Tyvek®) and thermoformed blisters have become the mainstream choice, prized for their clean appearance, excellent microbial barrier properties, and ease of device access. The core of this packaging system lies in the "seal." A loaded blister is hermetically heat-sealed to a breathable paper lid stock using a medical sealing machine, creating a reliable sterile barrier. A weak seal is akin to a dam breach—it nullifies all bacterial barrier functions and is absolutely unacceptable in medical device packaging. So, how do you systematically troubleshoot weak seals between breathable paper and blister packaging? This article categorizes the root causes into three key factors to help you pinpoint and resolve issues quickly.

Core Question: Is the raw material of the blister cup qualified with proper heat seal performance?

Material selection is the cornerstone of a successful seal in the medical thermoformed packaging industry. PETG material is the acknowledged industry benchmark because it inherently possesses excellent heat seal characteristics, allowing it to form strong bonds with breathable paper. Secondly, some specially modified PET materials can also meet the requirements. However, during troubleshooting, it is crucial to be highly alert to the potential misuse of standard, unmodified PET material. Standard PET has inherently poor heat seal performance; even under otherwise perfect conditions, it is highly likely to result in insufficient seal strength and sealing failure.

Core Question: Is the surface of the heat seal die perfectly flat and undamaged?

The heat seal die is the "executor" of the sealing task. It directly contacts the breathable paper, responsible for transferring heat and pressure. If this "executor" itself is flawed, the seal quality will inevitably suffer.

Uneven Surface:

Wear, corrosion, or contaminant buildup on the die surface leads to uneven pressure distribution. In areas with depressions or contaminants, insufficient pressure prevents effective sealing.

Damaged Die:

Visible impact damage or deformation will cause complete sealing failure in the corresponding areas.

Core Question: Are the time, temperature, and pressure parameters on the heat sealer optimized?

A perfect seal is the result of the precise collaboration of three parameters: time, temperature, and pressure. This is a dynamic balancing act—there is no universal "one-size-fits-all" setting.

Insufficient Temperature/Time:

The materials do not melt sufficiently, preventing effective molecular bonding and resulting in weak seal strength.

Excessively High Temperature/Prolonged Time:

This can cause the medical coating of the breathable paper to over-melt or even burn through, damaging its bacterial barrier structure and likewise causing seal failure.

Mismatched Pressure:

Insufficient pressure leads to inadequate material contact; excessive pressure can crush the packaging or cause improper displacement of molten material.

info@yinsopack.com

+86 15014837000(Wechat/WhatsApp/Skype)

NO.59 Meilin Road, Dalingshan Town, Dongguan City,Guangdong Province, China

Get a Free Prototype + Compliance Report Within 5 Days

Yinso Packing has been a leading figure in the medical packaging industry since 2007. We are committed to providing reliable, cost - effective, and innovative rigid thermoformed packaging solutions to top medical companies.

© 2025 Dongguan Yinso Medical Packaging Co.,Ltd All Rights Reserved.

AddressNO.59 Meilin Road, Dalingshan Town, Dongguan City,Guangdong Province, China

Emailinfo@yinsopack.com

Tel(Wechat/WhatsApp/Skype)+86 15014837000

About Us Medical Blister Packs Products Capabilities Blogs Contact Us