Welcome to Dongguan Yinso Medical Packaging Co.,Ltd.

Welcome to Dongguan Yinso Medical Packaging Co.,Ltd.

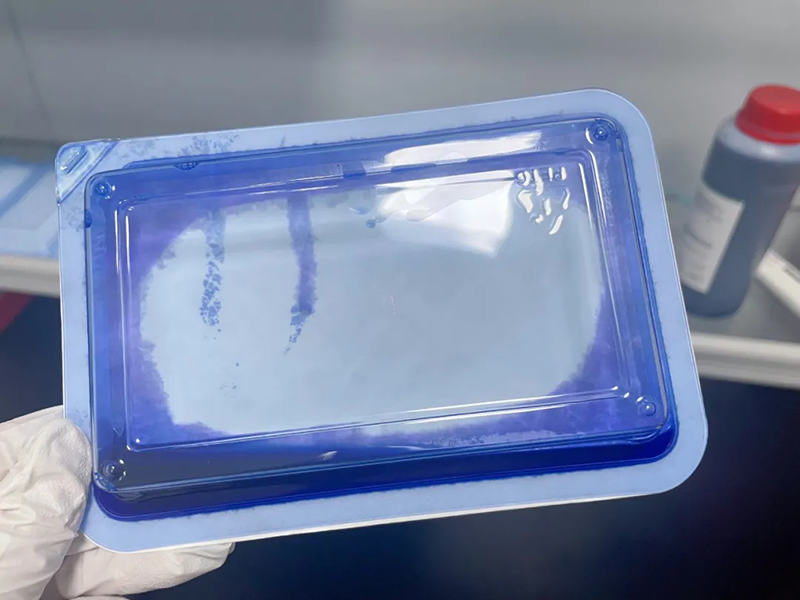

The integrity of medical blister pack seals acts as the "protective barrier" for the product, directly impacting the effectiveness of sterile barriers. Among various testing methods, the dye penetration test stands out as a common and powerful tool for evaluating the seal integrity of breathable packaging (e.g., Tyvek® + transparent film combinations) due to its intuitiveness, speed, and relatively low cost. Today, we'll break down the key aspects of this test, particularly the easily misleading "false positive" phenomena.

Core Objective: Detect whether there are leakage channels ≥50μm in the packaging seal edges (usually invisible to the naked eye).

Working Principle: A specially formulated dye solution is applied to the seal edges. If a leakage channel exists, the dye will penetrate and leave a visible stain on the inner side of the packaging within a specified time.

Standards:

Domestic: YY/T 0681.4-2010 "Test Methods for Sterile Medical Blister Pack – Part 4: Dye Penetration Test for Porous Packaging Seal Leaks"

International: ASTM F1929-2015

Dye Solution Preparation (Golden Formula):

Capillary agent (surfactant): 0.5% Triton X-100

Indicator dye: 0.05% Toluidine Blue

Solvent: 99.45% Water

(Precise formulation ensures test sensitivity and distinguishes true leaks from false positives!)

Fill the package with enough dye solution to cover the longest edge (~5mm depth).

Ensure the dye solution remains in contact with the seal edges.

Critical observation window: Inspect between 5 to 20 seconds after contact.

Too short (<5s): Micro-leaks may not yet be visible.

Too long (>20s): The dye may slowly seep through the breathable material (e.g., Tyvek®) due to capillary action, leading to false positives.

✅ Pass (No Leak): No visible blue channel-like penetration on the inner seal edge within 5–20 seconds. The packaging remains intact.

❌ Fail (True Leak): Within 1–2 seconds of contact, a clear, fast-forming blue channel appears along the seal edge, indicating a physical defect.

Observation:

Pouches/Trays: After >20 seconds (especially 30–40s or longer), a slow blue "bleeding" or "halo" appears on the breathable material (e.g., Tyvek® side) or around the seal area, mimicking a leak. However, no rapid channel-like penetration is observed within the critical 5–20s window.

The surfactant (Triton X-100) reduces surface tension, allowing the dye to slowly migrate through the natural microporous structure of breathable materials (e.g., Tyvek®) via capillary action.

Residual dye in the seal area may also slowly seep out over time.

info@yinsopack.com

+86 15014837000(Wechat/WhatsApp/Skype)

NO.59 Meilin Road, Dalingshan Town, Dongguan City,Guangdong Province, China

Get a Free Prototype + Compliance Report Within 5 Days

Yinso Packing has been a leading figure in the medical packaging industry since 2007. We are committed to providing reliable, cost - effective, and innovative rigid thermoformed packaging solutions to top medical companies.

© 2025 Dongguan Yinso Medical Packaging Co.,Ltd All Rights Reserved.

AddressNO.59 Meilin Road, Dalingshan Town, Dongguan City,Guangdong Province, China

Emailinfo@yinsopack.com

Tel(Wechat/WhatsApp/Skype)+86 15014837000

About Us Medical Blister Packs Products Capabilities Blogs Contact Us