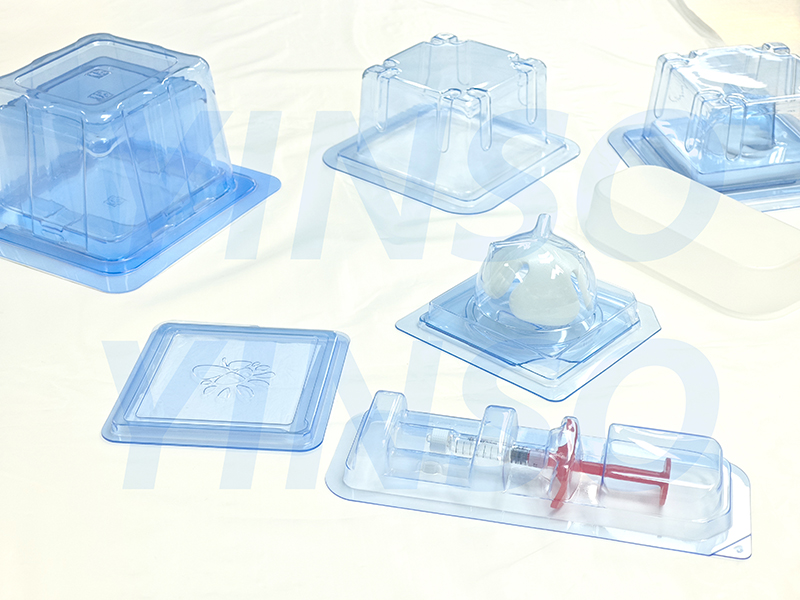

Both are blister trays—one for medical device packaging and the other for food packaging. Beneath their seemingly similar appearance lies a world of difference in risk.

When opening medical device packaging, we often see surgical instruments or implants neatly arranged inside a precision blister tray. On supermarket shelves, food is also commonly displayed in transparent blister packs.

Both types of blister trays fall under the supervision of food and drug regulatory agencies and come into contact with or directly/indirectly enter the human body. However, their risk levels and quality management requirements are fundamentally different.

From a risk management perspective, the irreplaceability of medical-grade blister trays over food-grade ones far exceeds common imagination.

1. Access Certification: Different Levels of "Admission Tickets"

In the international standards system, food packaging requires ISO 22000 Food Safety Management System certification, while medical device packaging must pass ISO 13485 Medical Device Quality Management System certification. Although both are third-party certifications, their core differences lie in material validation requirements and sterilization demands. Medical packaging validation procedures are more rigorous, with higher requirements for batch consistency.

China's medical device regulatory system is increasingly aligning with international standards. Previously, ISO 13485 certification for packaging material manufacturers was only a recommendation, but now it has become an industry standard. This change reflects the growing emphasis regulatory agencies place on risk management for medical device packaging. Medical packaging certification is directly linked to medical device product registration, a regulatory requirement fundamentally different from the market-access nature of food safety certification.

2. Material Selection: Risk Control at the Source

Medical-grade blister trays adhere to extremely stringent standards in raw material selection. From the initial raw material particles to the sheets used for molding, the controls and requirements for medical-grade products far exceed those for food-grade ones.

Medical-grade blister trays often use medical-grade PETG sheets. These materials must comply with ISO 10993 biocompatibility standards and ISO 11607 packaging validation requirements. They must provide a reliable microbial barrier, adapt to various sterilization methods, and possess good biocompatibility to prevent healthcare-associated infections.

For blister trays used with Class III medical devices, specific material grades, manufacturers, and quality standards are often designated, enabling full traceability from source to finished product. For example, an implant blister tray must ensure absolute material safety and traceability to meet stringent regulatory requirements.

This point-to-point material control is extremely rare in the food packaging field. Food packaging materials primarily focus on chemical migration and basic hygiene requirements, while medical materials must ensure safety and stability during prolonged contact with the human body.

3. Process Precision: The Quality Ceiling Determined by Molds

Molds are critical to blister tray forming, and the differences between medical-grade and food-grade trays in this aspect are particularly pronounced.

Medical device blister trays generally use high-precision aluminum alloy molds. These molds offer significant advantages in processing accuracy and stability, ensuring precise product dimensions, uniformity, and consistency, laying the foundation for subsequent heat-sealing processes.

Molds for food blister trays vary widely in quality. Apart from a few high-end products using aluminum molds, copper molds, plaster molds, etc., are common in the market. Particularly, copper molds with an inner plaster and outer copper structure may harbor mold over long-term use and have poor precision, making it difficult to meet the cleanliness and accuracy requirements for medical device packaging.

The core mission of medical molds is to ensure the integrity of the "microbial barrier," while food molds primarily serve product protection and display functions. Their precision requirements are not on the same level.

4. Production Environment: The Invisible Difference in Cleanliness

The production environment is a critical factor affecting blister tray quality. Medical-grade blister trays must be produced in cleanrooms with standards of Class 10,000 or higher. Packaging for some Class III medical devices, such as an implant blister pack, even requires localized Class 100 clean environments.

In contrast, the requirements for food-grade blister tray production environments are much more lenient. Many production lines cannot even guarantee a Class 300,000 cleanliness standard.

The core control metrics for medical-grade production environments are airborne particulate and microbial counts, aimed at keeping the product's initial bioburden at an extremely low level. This requirement is directly related to the effectiveness of subsequent sterilization processes.

Food production environments mainly focus on preventing foreign matter and general microbial contamination, lacking the strict philosophy prevalent in the medical field that treats the production environment as a prerequisite for sterilization process validity.

5. Validation Systems: The Divide in Scientific Rigor

Medical device packaging has a comprehensive, mandatory validation system, with the ISO 11607 series of standards at its core. This system covers the entire process from raw material qualification to final packaging system performance testing:

- Packaging materials must undergo biocompatibility, physical, and chemical performance tests.

- The molding and sealing processes require strict process validation.

- The final product must pass tests for sterile barrier system integrity, accelerated and real-time aging validation, and transport simulation validation.

These validations form a complete chain of evidence, available for regulatory review at any time. Food packaging validation is relatively simpler, focusing mainly on basic physical performance tests such as leakage, pressure resistance, and drop tests, lacking systematic and scientific mandatory requirements.

Medical packaging validation is essentially an evidence system proving its ability to consistently provide sterility assurance, whereas food packaging validation is a set of tests evaluating its basic protective functions. Their purposes and depths are fundamentally different.

6. The Essential Difference

When comparing medical-grade and food-grade blister trays side by side, we find they serve two distinct goals: life safety and product protection.

Medical device packaging, especially for sterile devices, is essentially part of the device's "life support system." Its failure can pose a direct life risk. For instance, the failure of an implant blister could lead to serious infections or surgical complications. In contrast, the failure of food packaging typically only results in product damage or sensory issues.

This fundamental difference in purpose dictates the vast gap in their risk management approaches.

Every step of medical device packaging—from material selection to final validation—answers one question: Can this packaging maintain the device's sterile state and safety performance throughout its entire shelf life?

As global medical device regulations become increasingly stringent, this risk-management-based irreplaceability will only become more pronounced. Choosing packaging that meets medical standards has become an inevitable choice for medical device manufacturers to control product risk and ensure patient safety.

Medical packaging and food packaging may seem similar, but in reality, they are separated by the distance of an entire risk management system.

Contact Us

- E-mail:

info@yinsopack.com

- Tel:

+86 15014837000(Wechat/WhatsApp/Skype)

- Address:

NO.59 Meilin Road, Dalingshan Town, Dongguan City,Guangdong Province, China

- 7x24 hours On Iine Service