Welcome to Dongguan Yinso Medical Packaging Co.,Ltd.

Welcome to Dongguan Yinso Medical Packaging Co.,Ltd.

In medical blister tray, the combination of a formed blister tray and a lidding material is one of the most common sterile barrier systems. Blister trays are typically manufactured from materials such as PETG, APET, PP, and HIPS. Forming methods include both pre-formed shells and reel-to-reel (in-line) thermoforming.Blister tray designs can be categorized as either flanged or non-flanged. Among these, flanged designs are often preferred due to their superior sealing performance.

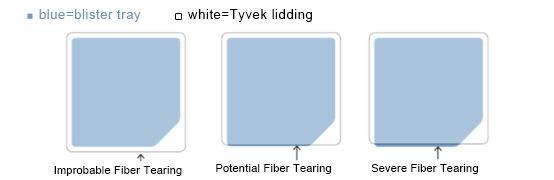

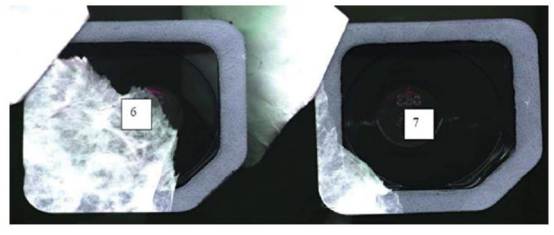

In practical applications involving medical blister trays sealed with medical-grade lidding, the ideal scenario during package opening is for the adhesive layer to fracture cohesively, leaving a uniform, white adhesive transfer pattern on the blister tray - achieving a clean peel. However, fiber tear within the lidding material can sometimes occur. This issue primarily stems from improper placement of the lidding material or suboptimal dimensional design.

While modern sealing equipment equipped with positioning pin systems can effectively address placement misalignment, scientifically sound dimensional design at the source is more critical. DuPont's experimental data clearly demonstrates this: when the lidding material was cut to the exact same dimensions as the blister tray, 26 out of 32 test samples exhibited varying degrees of fiber tear. Conversely, when the lidding material was designed to be at least 1mm larger than the blister tray in all dimensions, all samples achieved perfect clean peeling.

This improvement occurs because the appropriate dimensional overhang prevents adhesive from penetrating to the edge fibers of the Tyvek® substrate, thereby avoiding fiber tear during the peel process.

Therefore, to ensure reliable clean peel performance, the following practices are recommended:

1. Utilize blister trays with a flanged design.

2. Partnering with a reliable medical blister tray manufacturer is paramount. An experienced manufacturer can proactively identify and mitigate many potential issues early in the process.

3. Ensure the lidding material dimensions exceed those of the blister tray flange by a minimum of 1mm.

Attention to these design and supplier selection details will significantly enhance both the opening experience and the safety of the medical device package.

info@yinsopack.com

+86 15014837000(Wechat/WhatsApp/Skype)

NO.59 Meilin Road, Dalingshan Town, Dongguan City,Guangdong Province, China

Get a Free Prototype + Compliance Report Within 5 Days

Yinso Packing has been a leading figure in the medical packaging industry since 2007. We are committed to providing reliable, cost - effective, and innovative rigid thermoformed packaging solutions to top medical companies.

© 2025 Dongguan Yinso Medical Packaging Co.,Ltd All Rights Reserved.

AddressNO.59 Meilin Road, Dalingshan Town, Dongguan City,Guangdong Province, China

Emailinfo@yinsopack.com

Tel(Wechat/WhatsApp/Skype)+86 15014837000

About Us Medical Blister Packs Products Capabilities Blogs Contact Us