Welcome to Dongguan Yinso Medical Packaging Co.,Ltd.

Welcome to Dongguan Yinso Medical Packaging Co.,Ltd.

In medical blister tray packaging, packaging serves not only as the "outer garment" of products but more importantly as a Sterile Barrier System (SBS) ensuring patient safety. This system maintains the sterility of medical devices and drug-device combination products throughout their lifecycle—from production to use—preventing contamination and secondary injuries, thereby serving as the first line of defense in medical safety.

The mainstream medical blister tray formats include:

Medical dialysis bags

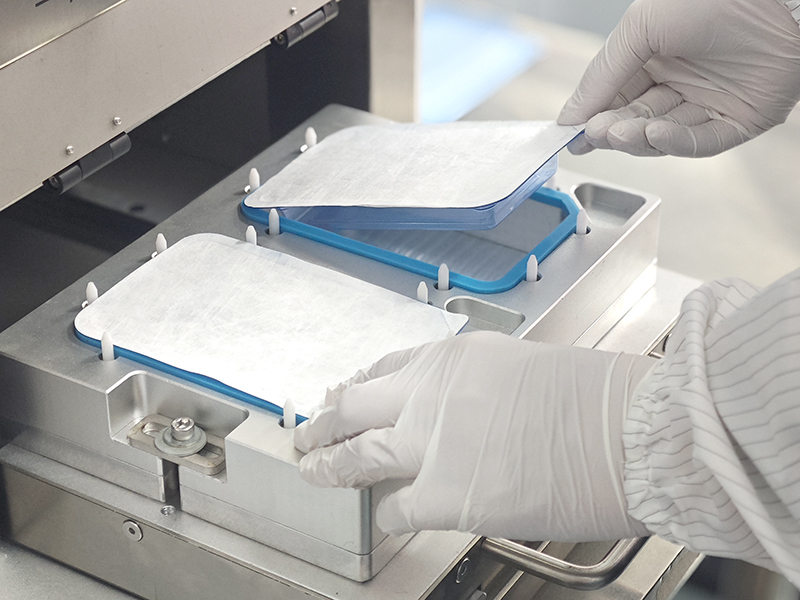

Medical blister trays + lid materials

Automatic blister packaging

Among these, medical blister tray + lid material combinations are widely used for high-end medical devices (e.g., implants, surgical instruments) and Class III medical devices (e.g., cardiovascular stents, orthopedic instruments) due to their superior protective properties and convenience.

The sterile barrier system is formed when lid materials are heat-sealed to blister trays, followed by sterilization. Ideal heat sealing must meet four critical requirements:

Seal strength compliance: Per EN 868-5:2018, adhesive-coated paper must achieve ≥1.5N/15mm without fiber tear

Continuous adhesive transfer: Visual inspection shows no breaks in adhesive application

Absence of micro-channels: Validated through dye penetration tests

Clean peelability: Ensures medical staff can open packaging without contamination risk

However, production environments present multiple challenges to heat sealing reliability. Below are five common heat sealing failure modes with corresponding solutions to optimize packaging processes.

Problem: Non-uniform adhesive transfer to medical blister tray, resulting in incomplete seals

Potential causes:

Contaminated sealing surface (mold release agents, glove residues)

Uneven sealer tooling surface (causing localized pressure variations)

Suboptimal sealing parameters (temperature/pressure/duration)

Solutions:

Surface cleaning: Wipe sealing surface with alcohol-soaked lint-free wipes

Tooling calibration: Verify and adjust sealer tooling flatness (laser-based flatness testing recommended)

Parameter optimization: Implement step-sealing (e.g., low-temperature pre-press followed by optimal sealing temperature)

Problem: Lid material delamination leaves paper residue on medical blister tray, compromising sterility

Potential causes:

Excessive sealing parameters (over-temperature/pressure/duration)

Poor lid design (e.g., full-perimeter sealing causing stress concentration)

Material incompatibility (e.g., insufficient fiber strength)

Solutions:

Parameter adjustment: Reduce temperature/pressure to balance strength and openability

Lid design optimization: Create unsealed margins (≥2mm edge buffer) and stepped structures (tray height differentials to reduce tear risk)

Material upgrade: Switch to high-strength adhesive-coated Tyvek® or medical composite films

Problem: Medical blister tray edge warping affects package integrity and sterilization compatibility

Potential causes:

Excessive sealing parameters causing thermal deformation

Structural/material inconsistencies (wall thickness variations, additive effects)

Solutions:

Reduce sealing parameters

Optimize medical blister tray design

Problem: Internal condensation appears in intact packages after transportation

Potential causes:

Extreme temperature/humidity fluctuations

Insufficient lid material breathability

Solutions:

Use high-breathability lid materials

Conduct simulated transport testing

Problem: Medical blister tray edges separate after ethylene oxide (EO) sterilization, breaching barrier integrity

Potential causes:

Gas shock during aeration (over-stacking or insufficient ventilation)

Surface contamination reducing bond strength

Solutions:

Optimize sterilization cycle parameters

Clean sealing surfaces: Remove contaminants with alcohol wipes

Enhance lid material breathability

info@yinsopack.com

+86 15014837000(Wechat/WhatsApp/Skype)

NO.59 Meilin Road, Dalingshan Town, Dongguan City,Guangdong Province, China

Get a Free Prototype + Compliance Report Within 5 Days

Yinso Packing has been a leading figure in the medical packaging industry since 2007. We are committed to providing reliable, cost - effective, and innovative rigid thermoformed packaging solutions to top medical companies.

© 2025 Dongguan Yinso Medical Packaging Co.,Ltd All Rights Reserved.

AddressNO.59 Meilin Road, Dalingshan Town, Dongguan City,Guangdong Province, China

Emailinfo@yinsopack.com

Tel(Wechat/WhatsApp/Skype)+86 15014837000

About Us Medical Blister Packs Products Capabilities Blogs Contact Us